The B-KOOL system: The refrigeration dryer from BAUER KOMPRESSOREN that extends filter cartridge capacity many times over

Rapid amortisation of procurement costs for the refrigeration dryer: Due to multiplication of the filter cartridge service lifetimes

Huge potential for savings: Thanks to reduction in consumption of original filter cartridges

Three different versions: for the new MINI-VERTICUS and VERTICUS, PE-VE Silent and BAUER compressors in open design.

In environments in which ambient temperatures are high in particular, the B-KOOL refrigeration dryer extends filter capacity almost beyond belief.

Operators benefit from much lower filter cartridge usage and storage costs in addition to longer interruption-free operation.

A clever approach to cutting costs and protecting the environment

The normal service life (capacity) of a filter cartridge can be extended many times over by additional cooling of the compressed air with the B-KOOL refrigeration dryer. As a result of air cooling, most of the condensate is separated in the oil and water separator, so that the filter cartridge absorbs much less water vapour.

The cost of purchasing the B-KOOL refrigeration dryer pays itself off within a short time, as the B-KOOK massively reduces consumption rates for original filter cartridges. As a result, running costs are virtually negligible.

Operation becomes even more cost-effective when the B-KOOL is used in conjunction with the B-SECURUS filter monitoring unit or B-DETECTION gas measurement system; the unit maximises filter cartridge life by optimising moisture content.

All the information you need at your fingertips!

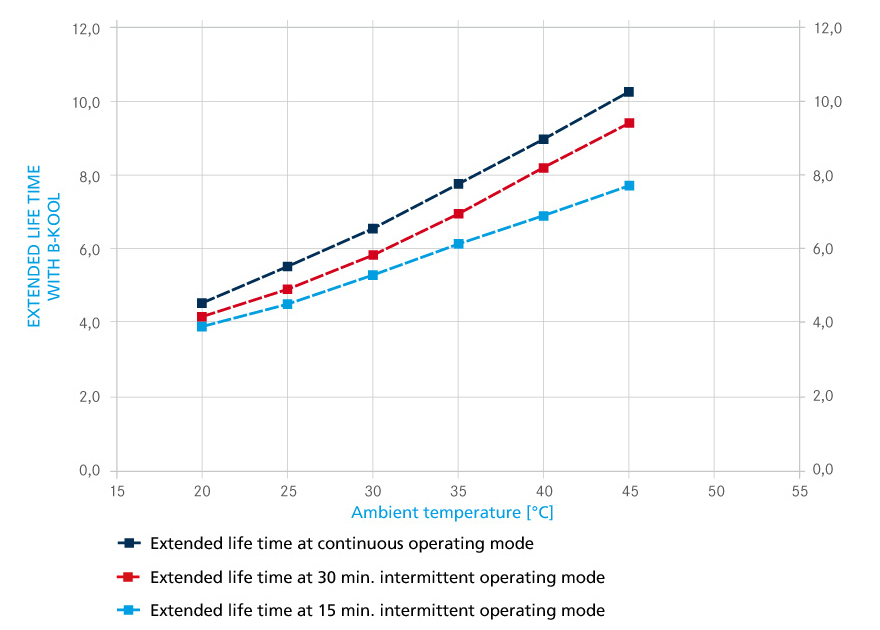

The following diagram illustrates the massive potential for savings that can be tapped into with B-KOOL.

EXTENDED LIFE TIME WITH B-KOOL AT VARIOUS OPERATING MODES

Service life calculated for P 61 filter system with SECURUS in conjunction with a BAUER compressor; based on 225 bar final pressure (185 bar average filling pressure) and continuous operation. Service lives will vary under other operating conditions and with different filling pressures.

How the B-KOOL refrigeration dryer works

The integrated cooling unit in the B-KOOL refrigeration dryer removes most of the moisture from the compressed air so that it cannot even get into the filter system. This extends the service life of the filter cartridge many times over.

For compliance with the limit values for hazardous substances specified in standard DIN EN 12021 for breathing air and in the interests of the safety of the compressor operator, only original BAUER parts must be used.

How it works at a glance

- The air saturated with moisture is fed out of the final separator of the compressor into the B-KOOL refrigeration dryer.

- In the high-efficiency cooling unit, the temperature of the compressed air, and thus its pressure dew-point, are reduced to approx. 3°C. For reasons of physics, the cooled air is no longer able to store the moisture content and the oil and water vapour turns to condensation.

- The condensate collects in the integrated separator and thus does not enter the filter cartridge.

- The condensate is discharged into the compressor unit‘s collecting container via the automatic condensate drain.

- The cooled and dried air is fed into the purification system by the B-KOOL refrigeration dryer.

- The B-KOOL control monitors the function of the integrated cooling technology and controls the condensate drain valve of the automatic condensate drain.

| Model | B-KOOL 680i, B-KOOL 680s and B-KOOL II 680i |

|---|---|

| Medium: | Air, nitrox (up to 40% O2), helium, argon |

| Ambient temperature: | +5°C to +45°C |

| Refrigerant: | R 134 a |

| Compressed air infeed temperature: | max. 60°C |

| Max. operating pressure compressed air: | 350 bar / 500 bar (550 bar B-KOOL II 680i) |

| Min. operating pressure compressed air: | 100 bar |

| Permissible free air delivery, compressor: | 200 – 700 l/min (10 l cylinder filling from 0 – 200 bar) 200 – 420 l/min (helium & argon) |

| Power supply: | 200 – 240 VAC 50/60 Hz |

| Power consumption: | max. 550 W at 50 Hz, 600 W at 60 Hz |

| Model | B-KOOL 680i | B-KOOL 680s | B-KOOL II 680i |

|---|---|---|---|

| Dimensions (L × W × H) | 775 × 535 × 347 mm | 395 × 563 × 695 mm | 792 × 550 × 390 mm |

| Approx. weight | 50 kg | 48 kg | 58 kg |