Recompressor units: For the recompression of bio-methane / natural gas in a higher-grade grid

Indirectly connected to bio-methane production, this application is the ideal system for seasonal balancing of fluctuations in transport and grid overloads.

Should a low-pressure line become overloaded (due to repeated bio-methane infeed, for example), excess natural gas / bio-methane mixture can be fed into a higher-grade grid.

This enables better use to be made of buffer volumes in high-pressure transport systems.

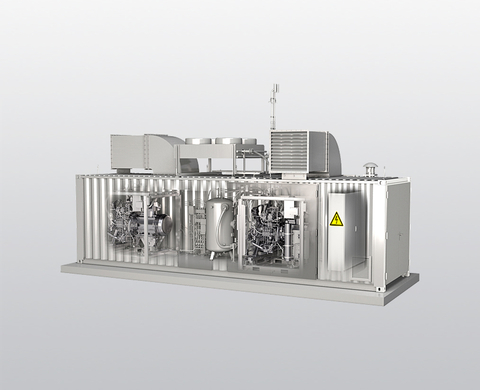

CS 23 – CS 52 series for the recompression of bio-methane / natural gas

This series has been developed and successfully introduced specifically for the recompression of natural gas (natural gas / bio-methane mixtures).

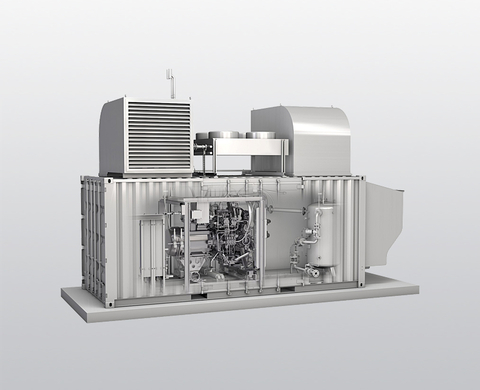

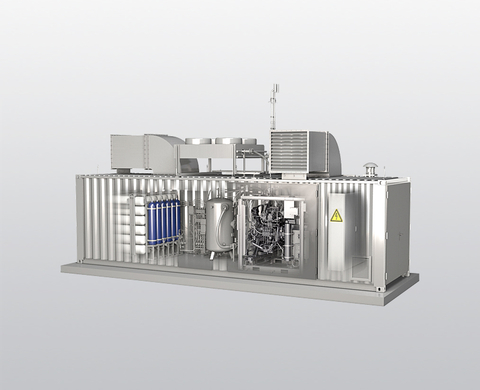

It is characterised in particular by its variable output pressure which can be adapted to a given grid pressure. The typical scope of delivery of a recompressor unit essentially comprises the compressor (recompressor), its electrical control system and the requisite high-pressure system.

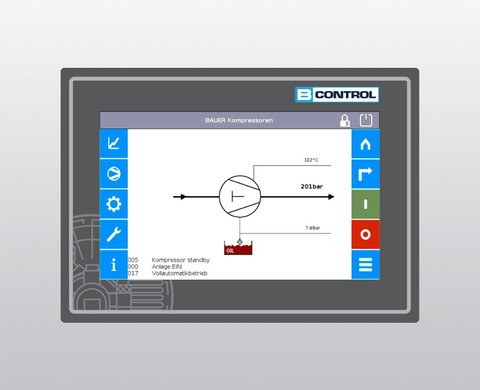

All the information you need at your fingertips!

Recompression (principle drawing)

Compressor control

BAUER's B-CONTROL III fully automatic compressor control regulates and monitors all functions of the natural gas filling station from gas input to filling device. Read more

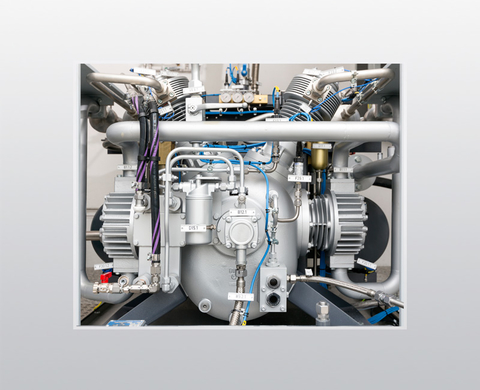

Compressor block

The BAUER compressor blocks have been designed specifically for CNG applications. Exceeding the requirements of all international safety standards, they are characterised by their high energy efficiency and reliability under the most demanding conditions. Read more

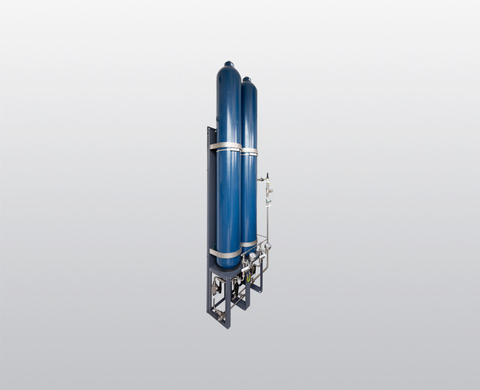

High-pressure gas treatment system

The high-pressure gas treatment system (high-pressure filter) is installed downstream of the compressor on the pressure side. Its primary function is to effectively remove excess moisture and possible oil deposits from the natural gas. Read more

Sound insulation and weather protection

The entire unit is integrated inside a housing made from concrete or steel for sound insulation and weather protection.

This provides the best possible protection against the most extreme ambient conditions and, thanks to the use of air handling units or heating systems, can be used in temperature ranges of ±55°C.

Tailored to meet your individual needs, our housings can be fitted with additional important options such as protection against sandstorms.

TÜV approval

During technical parts approval testing in the factory prior to delivery, the TÜV carries out comprehensive pressure and safety testing as well as testing the electrical equipment.

Installation/Commissioning

Our regional service teams deliver expert installation and commissioning including comprehensive operator induction. This ensures smooth operation at all times. Read more

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

Due to the large variance of the performance data required for bio-methane projects of this type we request that you direct any queries directly to us if you are interested.