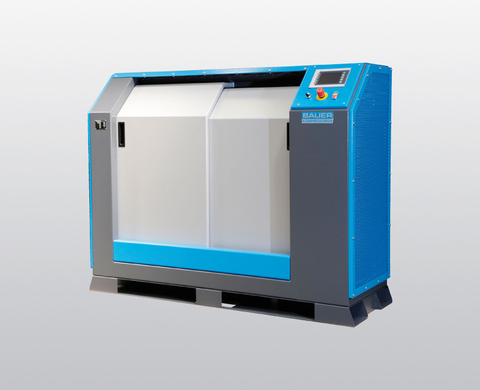

The BAUER B-NITROX MEMBRANE system

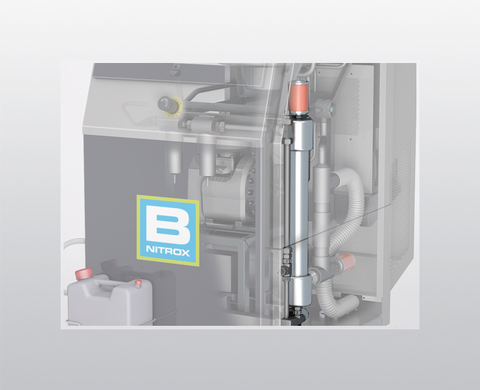

Nitrox optimised compressor: Compressor block optimised for high oxygen content and temperature monitoring of cooling air and in the final separator

Oxygen content independent of ambient temperature: Constant cooling of the membrane to ensure optimum efficiency at all times

Small footprint: Screw compressor, refrigeration dryer, filter and membrane unit are installed in a compact housing

B-MEMBRANE is BAUER's nitrox membrane system. This compressor system enriches breathing air with an increased oxygen content of up 40%.

With B-NITROX, BAUER is the only manufacturer in the world to offer a complete nitrox system certified by the TÜV. True to BAUER's uncompromising safety philosophy, all components have been perfectly matched.

The B-NITROX unit has been designed for reliable nitrox supply to stationary, professional diving centres, safari boats, live-aboards, yachts and cruise liners as well as for commercial diving missions.

The legislator has issued clear regulations, as the compression of gases requires a specific degree of tested safety.

This is an important consideration with regard to product liability in the event of accidents (in particular for tour operators and hotels who run diving centres on their sites).

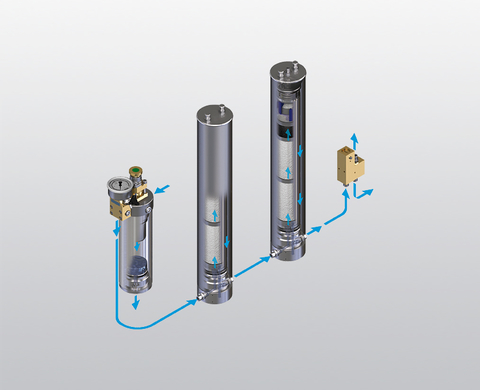

The components of the BAUER B-NITROX MEMBRANE system

All the information you need at your fingertips!

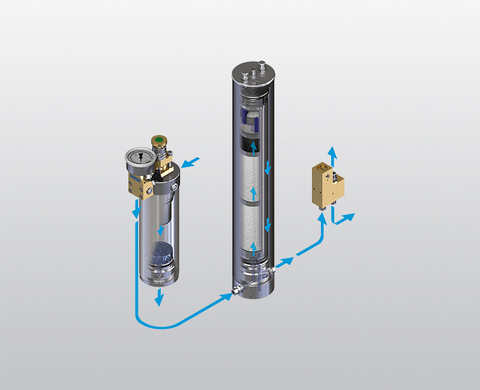

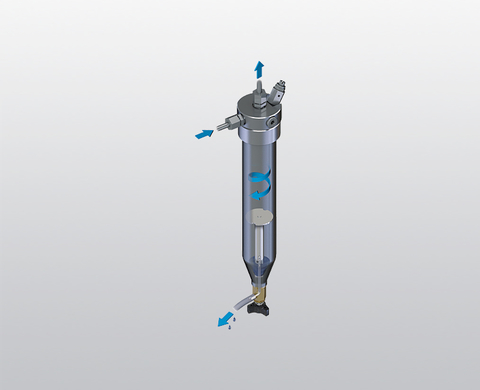

Refrigerant dryer

Refrigerant dryer for efficient cooling and condensate separation. Enables oxygen mixture to be produced irrespective of the ambient temperature: the continuously cooled membrane delivers optimum efficiency at all times Filter system reliably removes oil and particulate to protect the membrane from harmful influences and extend its service life.

P 61 Purification system

When used in conjunction with original BAUER filter cartridges, the P 61 purification system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021:2014¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 2400 m³ of air can be treated.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

Temperature monitoring in the final separator and the cooling air

For your safety, all BAUER B-NITROX compressors are equipped with temperature sensors for monitoring the cooling air and in the final separator. Here, compliance with the specified operating temperature is reliably monitored.

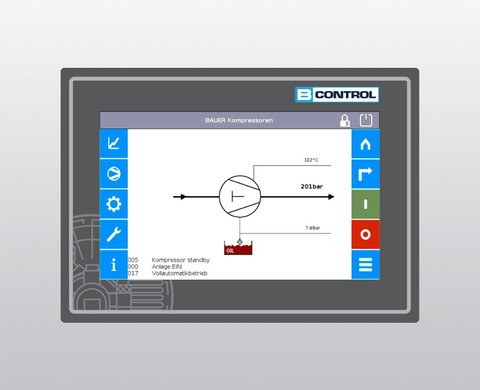

B-CONTROL III

B-CONTROL III is BAUER's premium control system for demanding applications. B-CONTROL III can be flexibly adapted to your individual requirements and, if necessary, expanded to control complete system processes. Read more

B-SAFE 300-OX

Ensures the uncompromising safety of persons and compressor rooms when filling pressure cylinders. As a result of filling accidents arising from exploding cylinders, explosion protection is already standard or is prescribed in many countries.

B-SAFE replaces costly protective measures in compressor rooms and provides operators with a high level of legal security.

Paint finish/Special paint finish

All frame parts of BAUER compressors are finished with a sophisticated powder coating. Read more

B-SECURUS filter monitoring

The B-SECURUS system monitors the saturation of the filter cartridge(s) by measuring the moisture in the molecular sieve. Read more

Filling device 4 × 200 bar Nitrox

The filling device consists of four flexible UNIMAM high-pressure filling hoses and one filling valve each for 200 bar according to DIN EN 144-3. The integrated final pressure gauge makes it easy to read off the final pressure on the high-pressure compressor.

P 81 Purification system

When used in conjunction with original BAUER filter cartridges, the P 81 filter system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021:2014¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 5,200 m³ of air can be treated.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

Additional intermediate separator after the first stage

In the case of operation in locations where air humidity is high (tropical regions, for example), we recommend installing a separator downstream of the first compressor stage. This can extend the service life of the unit and reduce maintenance costs.

Intermediate pressure gauge kit

The intermediate pressure gauges show the operating pressure of the individual compressor stages. This information about the pressure is used to check the corresponding stage valves (inlet and outlet) for leaks so that potential faults can be detected quickly. The intermediate pressure gauges are installed inside the compressor housing.

60 l condensate collection system

This convenient system provides a central collection point for the condensate (oil and water mixture) produced during the compression process inside the compressor. The condensate tank features an integrated float switch which can be relied upon to monitor the level of condensate in the tank and provides protection against overfilling. A combined silencer and filter unit prevents pollution caused by noise or odour.

B-KOOL III refrigeration dryer

In environments in which ambient temperatures are high in particular, the B-KOOL III refrigeration dryer extends filter capacity almost beyond belief. Operators benefit from much lower filter cartridge usage and storage costs in addition to longer interruption-free operation. Read more

AERO-GUARD

Using the AERO-GUARD reduces the CO2 content of the breathing air to approximately one-third of the intake value. The constantly increasing levels of CO2 concentration in the air resulting from unfavourable environmental influences are making it more and more difficult for the operators of filling stations to be sure of achieving compliance with legally binding maximum limits for CO2. With AERO-GUARD the operator is always on the safe side! Read more

Scope of delivery of the modules

LOW PRESSURE MODULE, PURIFICATION MODULE, OX MODULE, HIGH PRESSURE MODULE. Read more

| Type designation | Oxygen content | Compressor charging rate ¹ | Max. operating pressure | Motor / motor output | Net weight approx. | Dimensions L × W × H | |||

|---|---|---|---|---|---|---|---|---|---|

| % | l/min | cfm | bar | psig | Motor | kW | kg | cm | |

| B-MEMBRANE 260/32 | 32 | 260 | 9,2 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 7,5 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 320/32 | 32 | 320 | 11,5 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 11 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 550/32 | 32 | 550 | 20 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 15 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 700/32 | 32 | 700 | 25 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 15 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 320/36 | 36 | 320 | 11,5 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 11 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 550/36 | 36 | 550 | 20 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 15 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 700/36 | 36 | 700 | 25 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 18,5 | 600 | 165 × 84 × 182 |

| B-MEMBRANE 320/40 | 40 | 320 | 11,5 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 15 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 550/40 | 40 | 550 | 20 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 18,5 | 600 | 165 × 84 × 182 |

¹ Measured by cylinder filling from 0–200 bar (0–3000 psi), ± 5 %

Downloads for the BAUER B-NITROX membrane system

B-NITROX Systems – The safe and secure solution for producing and compressing nitrox

BAUER B-NITROX MEMBRANE system

BAUER B-NITROX MEMBRANE system