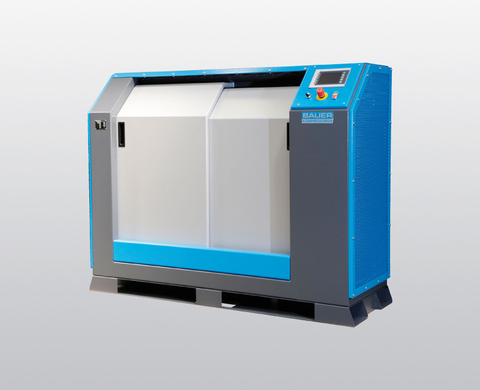

PE-NITROX MEMBRANE: The Reliable Solution for Nitrox Production

Robust membrane system with a small footprint

CE-certified

The BAUER PE-NITROX MEMBRANE offers an efficient solution for nitrox production with up to 40% oxygen content. This sophisticated system enables safe and long-lasting nitrox production in various environments, and is ideal for continuous operation. The membrane system is characterised by its low-maintenance components, making it particularly user-friendly and reliable.

The hardwire control unit is mounted on the front of the housing, while the SUPER SILENT housing design integrates the low-pressure compressor, refrigerant dryer, and filter system to save space. The membrane module is installed on the outter side wall of the unit.

All the information you need at your fingertips!

Refrigerant dryer

Refrigerant dryer for efficient cooling and condensate separation. Enables oxygen mixture to be produced irrespective of the ambient temperature: the continuously cooled membrane delivers optimum efficiency at all times Filter system reliably removes oil and particulate to protect the membrane from harmful influences and extend its service life.

B-SAFE 300-OX

Ensures the uncompromising safety of persons and compressor rooms when filling pressure cylinders. As a result of filling accidents arising from exploding cylinders, explosion protection is already standard or is prescribed in many countries.

B-SAFE replaces costly protective measures in compressor rooms and provides operators with a high level of legal security.

Paint finish/Special paint finish

All frame parts of BAUER compressors are finished with a sophisticated powder coating. Read more

AERO-GUARD

Using the AERO-GUARD reduces the CO2 content of the breathing air to approximately one-third of the intake value. The constantly increasing levels of CO2 concentration in the air resulting from unfavourable environmental influences are making it more and more difficult for the operators of filling stations to be sure of achieving compliance with legally binding maximum limits for CO2. With AERO-GUARD the operator is always on the safe side! Read more

| Version | Max. Oxygen Content | Charging Rate HP-Nitrox-Compressor ¹ | Net weight approx. | Dimensions L × W × H | |

|---|---|---|---|---|---|

| % | l/min | cfm | kg | cm | |

| PE-NITROX 260 B AS32 | 32 | 260 | 7.5 | 480 | 115 × 89 × 135 |

| PE-NITROX 320 B AS32 | 32 | 320 | 11 | 480 | 115 × 89 × 135 |

| PE-NITROX 320 B AS36 | 36 | 320 | 11 | 480 | 115 × 89 × 135 |

| PE-NITROX 320 B AS40 | 40 | 320 | 15 | 480 | 115 × 89 × 135 |

| PE-NITROX 550 B AS32 | 32 | 550 | 15 | 480 | 115 × 89 × 135 |

| PE-NITROX 550 B AS36 | 36 | 550 | 15 | 480 | 115 × 89 × 135 |

| PE-NITROX 550 B AS40 | 40 | 550 | 18.5 | 550 | 130 × 105 × 145 |

| PE-NITROX 700 B AS32 | 32 | 700 | 15 | 480 | 115 × 89 × 135 |

| PE-NITROX 700 B AS36 | 36 | 700 | 18.5 | 550 | 130 × 105 × 145 |

¹ Measured by cylinder filling (11.1 l) from 0 - 200 bar/ 2900 psig, ±5% at 20 degrees Celsius ambient temperature