The BAUER B-NITROX MEMBRANE system

Nitrox optimised compressor: Compressor block optimised for high oxygen content and temperature monitoring of cooling air and in the final separator

Oxygen content independent of ambient temperature: Constant cooling of the membrane to ensure optimum efficiency at all times

Small footprint: Screw compressor, refrigeration dryer, filter and membrane unit are installed in a compact housing

B-MEMBRANE is BAUER's nitrox membrane system. This compressor system enriches breathing air with an increased oxygen content of up 40%.

With B-NITROX, BAUER is the only manufacturer in the world to offer a complete nitrox system certified by the TÜV. True to BAUER's uncompromising safety philosophy, all components have been perfectly matched.

The B-NITROX unit has been designed for reliable nitrox supply to stationary, professional diving centres, safari boats, live-aboards, yachts and cruise liners as well as for commercial diving missions.

The legislator has issued clear regulations, as the compression of gases requires a specific degree of tested safety.

This is an important consideration with regard to product liability in the event of accidents (in particular for tour operators and hotels who run diving centres on their sites).

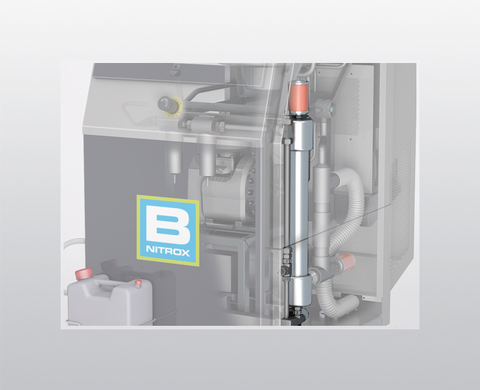

The components of the BAUER B-NITROX MEMBRANE system

All the information you need at your fingertips!

Refrigerant dryer

Refrigerant dryer for efficient cooling and condensate separation. Enables oxygen mixture to be produced irrespective of the ambient temperature: the continuously cooled membrane delivers optimum efficiency at all times Filter system reliably removes oil and particulate to protect the membrane from harmful influences and extend its service life.

Paint finish/Special paint finish

All frame parts of BAUER compressors are finished with a sophisticated powder coating. Read more

| Type designation | Oxygen content | Compressor charging rate ¹ | Max. operating pressure | Motor / motor output | Net weight approx. | Dimensions L × W × H | |||

|---|---|---|---|---|---|---|---|---|---|

| % | l/min | cfm | bar | psig | Motor | kW | kg | cm | |

| B-MEMBRANE 260/32 | 32 | 260 | 9,2 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 7,5 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 320/32 | 32 | 320 | 11,5 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 11 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 550/32 | 32 | 550 | 20 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 15 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 700/32 | 32 | 700 | 25 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 15 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 320/36 | 36 | 320 | 11,5 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 11 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 550/36 | 36 | 550 | 20 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 15 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 700/36 | 36 | 700 | 25 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 18,5 | 600 | 165 × 84 × 182 |

| B-MEMBRANE 320/40 | 40 | 320 | 11,5 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 15 | 420 | 165 × 85 × 152 |

| B-MEMBRANE 550/40 | 40 | 550 | 20 | 225 | 3200 | Three-phase current 400 V, 50 Hz | 18,5 | 600 | 165 × 84 × 182 |

¹ Measured by cylinder filling from 0–200 bar (0–3000 psi), ± 5 %

Downloads for the BAUER B-NITROX membrane system

B-NITROX Systems – The safe and secure solution for producing and compressing nitrox

BAUER B-NITROX MEMBRANE system

BAUER B-NITROX MEMBRANE system