MARINER II-Diesel – The mobile breathing air compressor with incredible power and impressive professional qualities

Tough: Thanks to an incredibly durable driving gear. Suitable for short-term operation and continuous service

Reliable lubrication: With zero-maintenance low-pressure oil pump

Dimensioned for the toughest climate conditions: Operational reliability no matter what in professional applications

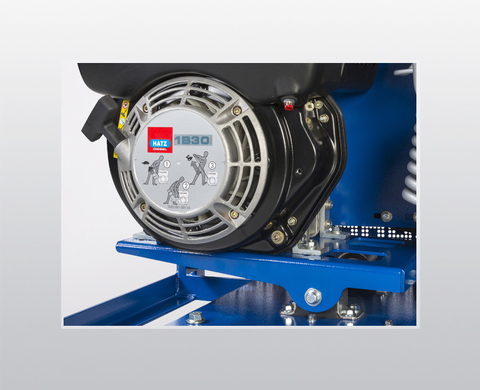

With proven Hatz diesel drive as standard: Tailor-made for use in any location

The MARINER II-D by BAUER KOMPRESSOREN is a robust and extremely durable breathing air compressor in the PROFI-LINE series which combines a Hatz diesel engine as standard with 170 l/min FAD. It is ideal for both short-term operation and demanding continuous service.

The integrated BAUER P 21 SUPER-TRIPLEX filter system delivers clean air for safe diving: The advanced filter technology of the BAUER TRIPLEX filter can be relied upon to protect divers and fire crews against breathing in air impurities and provide effective protection against icing up.

An incredibly durable compressor block and corrosion-resistant components make this unit suitable for use even under the toughest climate conditions. Furthermore, the crash frame constructed from steel profiles ensures excellent rigidity and provides outstanding protection for the unit.

Thanks to 3-stage construction and the use of industrial bearings, this advanced series is able to deliver long service life and constant intrinsic value in demanding professional applications.

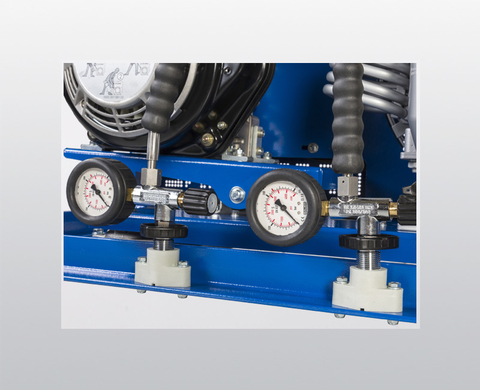

All the information you need at your fingertips!

IK 120 compressor block

The BAUER IK 120 series compressor block has been designed for the most demanding professional applications. Dimensioned for more than 30,000 operating hours, it has proven its worth in thousands of application scenarios. Read more

P 21 filter system

When used in conjunction with original BAUER filter cartridges, the P 21 filter system with integrated oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 140 m³ of air can be treated.

¹ If the units are maintained and installed correctly as described in the operating instructions or user manual and if the concentration of CO2 in the intake air does not exceed the values specified in the applicable standard for breathing air.

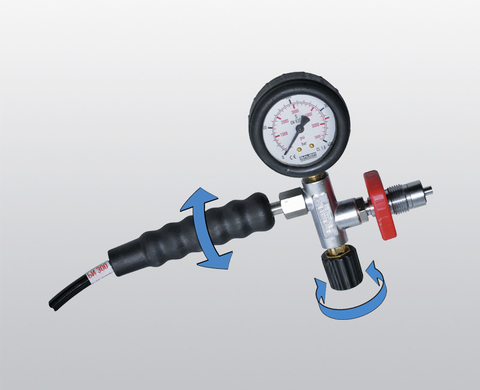

Filling device

The filling device comprises a flexible "UNIMAM" high-pressure filling hose and filling valve complete with final pressure gauge. The final pressure gauge makes it easy to read off the filling pressure. It is protected against damage by a durable rubber jacket.

Filling hose

High-quality UNIMAM high-pressure filling hoses made from food-safe and long-life hose material make for flexible and safe handling. Swivel hose connections enable the filling valve to be connected to the breathing air cylinder quickly, easily and safely.

B-TIMER filter cartridge monitoring

The operating hours and the current level of cartridge saturation are displayed on the unique B-TIMER mini-computer. Read more

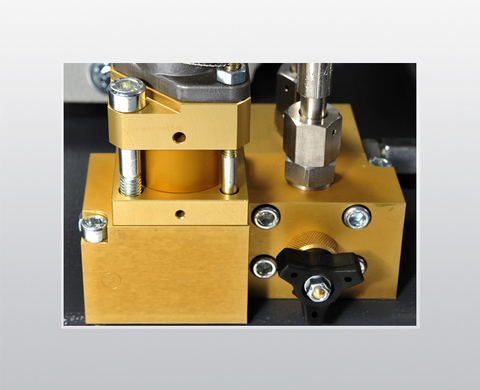

Switch-over device PN 300/200 bar

For easy and flexible switching from 200 to 300 bar and vice versa. Read more

Trolley

The trolley provides an easy and convenient mode of transport for mobile compressor units. Fitted with pneumatic tyres, the trolley maximises mobility.

Telescopic intake tube

The telescopic intake tube is highly recommended when operating compressor units with a combustion engine. It avoids the intake of exhaust gases that are harmful to health.

Paint finish/Special paint finish

All frame parts of BAUER compressors are finished with a sophisticated powder coating. Read more

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

| Type designation | Charging rate ¹ | Drive | Net weight | Dimensions L × W × H | |

|---|---|---|---|---|---|

| l/min | Motor | kW | approx. kg | cm | |

| MARINER II-D | 170 | Diesel engine | 5.0 | 158 | 110 × 58 × 62.5 |

¹ Measured with cylinder filling (10 l) from 0 to 200 bar, ±5%

Downloads for the PROFI-LINE compressors and compressor accessories

THE NEW PROFI-LINE – Redefining Mobility

BAUER PREMIUM LINE – Compressors for sports & safety applications