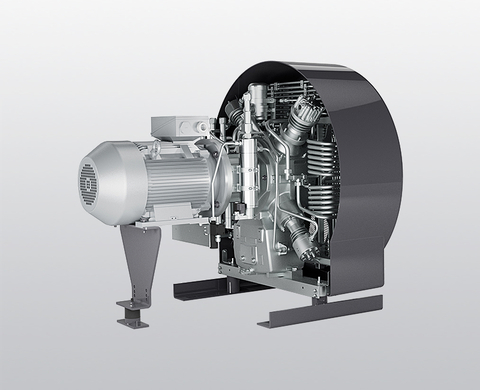

G series K 22 – K 25: High-pressure compressors for helium, argon and neon in a horizontal design with robust dimensioning for applications such as helium recovery and noble gas bottling

Very easy to maintain: Thanks to proven BAUER system components

Cost-efficient: Low installation overhead combined with cost-effective operation

Optimum free air delivery rates for your application: For the compression of helium, argon and other noble gases

Comprehensive assurance of spare parts supply: With the global BAUER Service and Support network

The large-scale, high-pressure industrial series by BAUER KOMPRESSOREN impresses as an optimised, gas-tight option for the compression of helium, argon and other noble gases.

Recirculation of blowby and lost gas from the automatic condensate drain into the intake buffer combined with efficient encapsulation of the safety valves effectively minimises gas losses.

Low speeds and optimised grading of the compressors provide the basis for the very best compression ratios for the compression of noble gases.

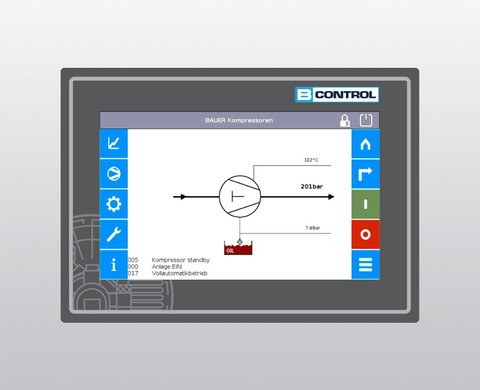

All the information you need at your fingertips!

B-CONTROL MICRO compressor control

The B-CONTROL MICRO is a modern, easy-to-use compressor control with colour display for the control and reliable monitoring of all basic functions. Read more

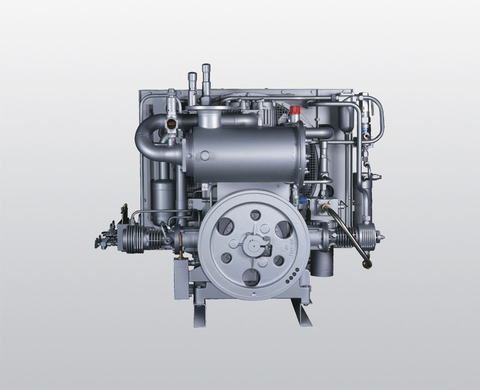

Helium configuration

The heavy-duty units for helium are characterised by minimum gas losses. Read more

Compressor block

The standard block series is air-cooled and designed for demanding industrial applications. Read more

B-CONTROL III

B-CONTROL III is BAUER's premium control system for demanding applications. Read More

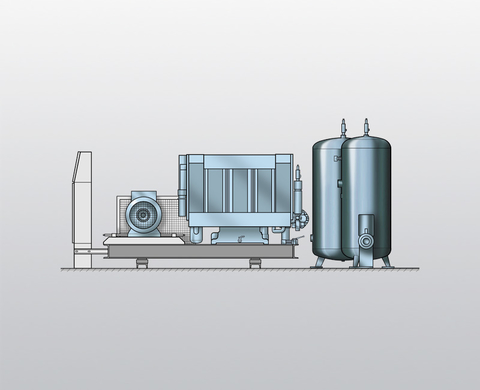

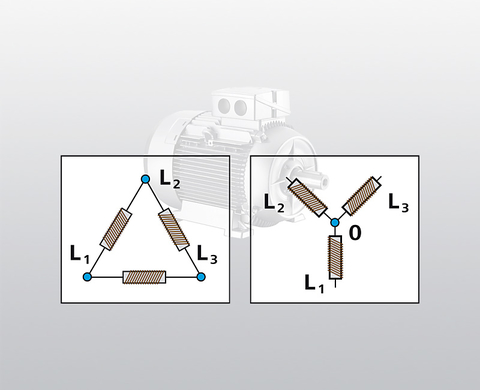

Start-up configuration

At and above motor power ratings of 75 kW and in conjunction with the B-CONTROL, a soft starter to protect the unit during starting and effectively reduce starting current is used as standard. The technical alternative is soft staring with a frequency inverter. Read more

Monitoring of pressure and temperature

This add-on module for the B-CONTROL control monitors the pressures and temperatures of all compressor stages. Read more

Treatment systems

BAUER treatment systems for highly compressed air and gases reduce content such as moisture, oil and particles to a permissible level. Read more

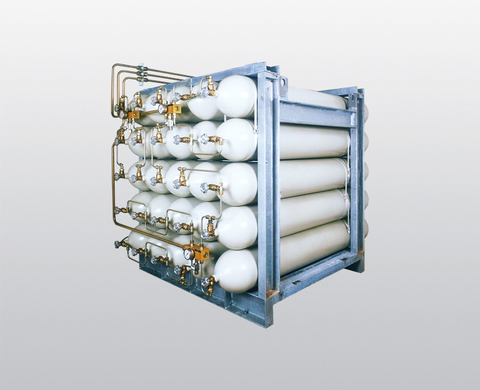

Storage systems

Modular high-pressure storage systems by BAUER KOMPRESSOREN are the ideal way to expand a compressor system. Read more

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

| Type designation | Effective free air delivery ¹ | Max. operating pressure ² | Number of compressor stages | Speed approx. | Motor output | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | bar | psig | rpm | kW | kg | lbs | ||

150 – 230 bar, air-cooled | ||||||||||

| G 25.9-45 | 1520 | 91 | 54 | 230 | 3350 | 5 | 1180 | 45 | 1780 | 3920 |

120 – 320 bar, air-cooled | ||||||||||

| G 22.6-22 | 600 | 36 | 21.2 | 320 | 4640 | 4 | 985 | 22 | 820 | 1810 |

| G 22.6-30 | 900 | 54 | 31.8 | 320 | 4640 | 4 | 1485 | 30 | 890 | 1960 |

200 – 350 bar, air-cooled | ||||||||||

| G 22.5-22 | 650 | 39 | 23 | 350 | 5100 | 5 | 985 | 22 | 890 | 1960 |

| G 22.5-30 | 1000 | 60 | 35.3 | 350 | 5100 | 5 | 1485 | 30 | 960 | 2115 |

| G 25.9-45 | 1320 | 79 | 47 | 350 | 5100 | 5 | 1050 | 45 | 1780 | 3920 |

| G 25.18-55 | 1800 | 108 | 64 | 350 | 5100 | 5 | 1100 | 55 | 1950 | 4290 |

| Type designation | Effective free air delivery ¹ | Max. operating pressure ² | Number of compressor stages | Speed approx. | Motor output | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | bar | psig | rpm | kW | kg | lbs | ||

120 – 320 bar, air-cooled | ||||||||||

| G 22.6-22 | 700 | 42 | 24.7 | 320 | 4640 | 4 | 1170 | 22 | 820 | 1810 |

| G 22.6-30 | 1070 | 64.2 | 37.8 | 320 | 4640 | 4 | 1770 | 30 | 890 | 1960 |

200 – 350 bar, air-cooled | ||||||||||

| G 22.5-22 | 800 | 48 | 28.2 | 350 | 5100 | 5 | 1170 | 22 | 890 | 1960 |

| G 22.5-30 | 1200 | 72 | 42.4 | 350 | 5100 | 5 | 1770 | 30 | 960 | 2115 |

¹ Free air delivery according to ISO 1217, power consumption at maximum final pressure under certain conditions, each valid for helium. Other ambient conditions result in different performance data.

² Max. operating pressure = max. safety valve pressure setting; reduced switch-off pressure.

Values for other noble gases are available on request.

Downloads for the BAUER air-cooled helium and argon compressors

HELIUM RECOVERY – COMPRESSORS & SYSTEMS

BAUER Compressors for Industry – Tailored to your requirements