K 22 – K 28 Series – Powerful compressor units for demanding applications

Very easy to maintain: Thanks to proven BAUER system components

Cost-efficient: Low installation overhead combined with cost-effective operation

Designed for demanding operating conditions: With optimum free air delivery rates and a variety of drive power ratings

Comprehensive assurance of spare parts supply: With the global BAUER Service and Support network

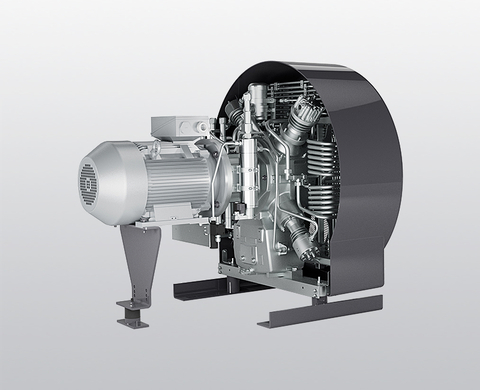

Whether they're found in standard compressed-gas applications in industry or built into vehicles for mobile use: The air-cooled high-pressure compressor units in the K 22 – K 28 series are reliable, durable and the solution of choice for demanding customers.

Outstanding ease of maintenance is just as much a matter of course for us as the wide range of possible applications – optimally matched to your specific needs.

The units of the new K 22 series are designed with direct coupling, while the units K 23 – K 28 are driven by means of V-belts.

In line with your individual needs and industrial requirements, BAUER KOMPRESSOREN can also provide you with tailor-made turnkey system solutions.

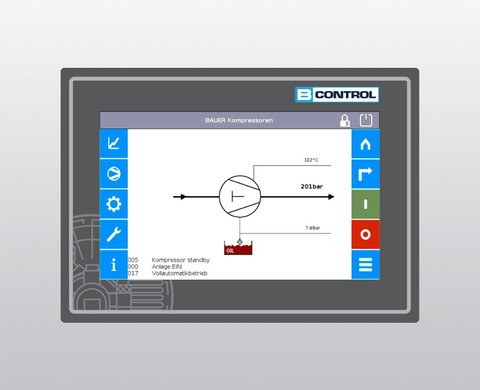

All the information you need at your fingertips!

B-CONTROL MICRO compressor control

The B-CONTROL MICRO is a modern, easy-to-use compressor control with colour display for the control and reliable monitoring of all basic functions. Read more

The system concept

The compressor units are equipped with vibration dampers and allow installation without foundations. Read more

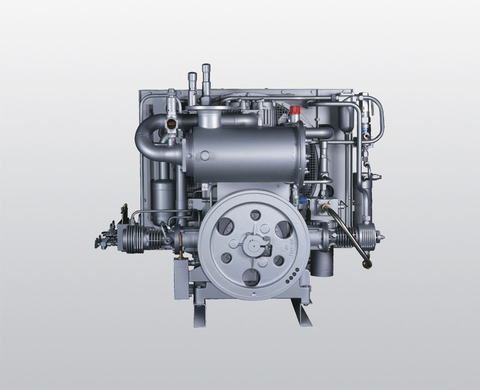

Compressor block

The standard block series is air-cooled and designed for demanding industrial applications. Read more

B-CONTROL III

B-CONTROL III is BAUER's premium control system for demanding applications. Read More

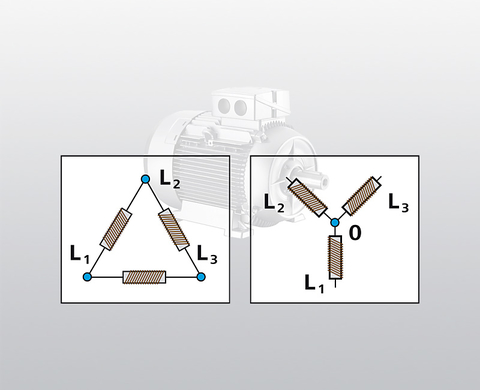

Start-up configuration

At and above motor power ratings of 75 kW and in conjunction with the B-CONTROL, a soft starter to protect the unit during starting and effectively reduce starting current is used as standard. The technical alternative is soft staring with a frequency inverter. Read more

Monitoring of pressure and temperature

This add-on module for the B-CONTROL control monitors the pressures and temperatures of all compressor stages. Read more

Intake system

The intake system supplies the compressor with air or gas at a suitable and monitored intake pressure. Read more

Intake pressure reduction

IIntake pressure reduction ensures that the compressor takes in the gas at the appropriate pressure. The level of intake pressure reduction is adjusted according to prevailing gas pressure and required intake pressure. Integrated safety valves and pressure monitoring effectively ensure that intake pressure does not fall below or above the permissible level.

Intake buffer vessel

To effectively prevent pulsations in the intake area, an intake buffer vessel is installed between the compressor and the upstream gas supply networks and/or control equipment. Read more

60-litre condensate vessel

The generous 60 l condensate collection system provides a central collection point for the condensate produced during the compression process inside the compressor. Read more

Treatment systems

BAUER treatment systems for highly compressed air and gases reduce content such as moisture, oil and particles to a permissible level. Read more

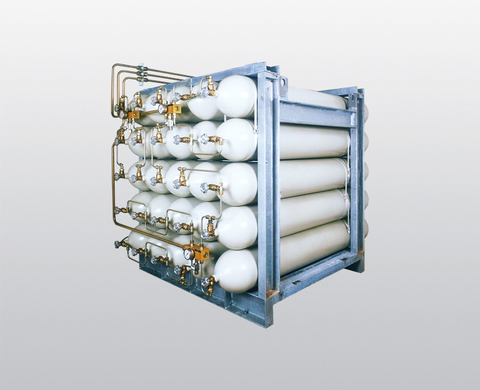

Storage systems

Modular high-pressure storage systems by BAUER KOMPRESSOREN are the ideal way to expand a compressor system. Read more

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

| Type designation | Effective free air delivery ¹ | Max. operating pressure ² | Number of compressor stages | Speed approx. | Motor output | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | bar | psig | rpm | kW | kg | lbs | ||

High-pressure compressor K 22 – K 28, 900 – 3500 l/min, 90 – 370 bar | ||||||||||

| I 22.0-22 | 900 | 54 | 31.8 | 370 | 5370 | 4 | 985 | 22 | 710 | 1565 |

| I 22.0-30 | 1300 | 78 | 45.9 | 370 | 5370 | 4 | 1485 | 30 | 780 | 1715 |

| I 23.0-37 | 1480 | 89 | 52 | 350 | 5000 | 4 | 1400 | 37 | 780 | 1715 |

| I 25.0-45 | 1900 | 114 | 67 | 350 | 5000 | 4 | 1180 | 45 | 1750 | 3850 |

| I 28.0-55 | 2500 | 150 | 88 | 350 | 5000 | 4 | 830 | 55 | 1860 | 4090 |

| I 28.0-75 | 3500 | 210 | 125 | 350 | 5000 | 4 | 1180 | 75 | 1950 | 4290 |

High-pressure compressor K 22 – K 28, 900 – 1300 l/min, 350 – 450 bar | ||||||||||

| I 22.0-22 | 900 | 54 | 31.8 | 450 | 6525 | 4 | 985 | 22 | 710 | 1565 |

| I 22.0-37 | 1300 | 78 | 45.9 | 450 | 6525 | 4 | 1485 | 37 | 830 | 1830 |

High-pressure compressor K 22 – K 28, 1300 – 2300 l/min, 420 – 525 bar | ||||||||||

| I 22.5-30 | 1300 | 78 | 45.9 | 525 | 7600 | 5 | 1480 | 30 | 850 | 1875 |

| I 25.9-45 | 1900 | 114 | 67 | 500 | 7200 | 5 | 1180 | 45 | 1900 | 4180 |

| I 25.18-55 | 2300 | 138 | 81 | 500 | 7200 | 5 | 1100 | 55 | 1950 | 4290 |

| Type designation | Effective free air delivery ¹ | Max. operating pressure ² | Number of compressor stages | Speed approx. | Motor output | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | bar | psig | rpm | kW | kg | lbs | ||

High-pressure compressor K 22 – K 28, 920 – 1300 l/min, 90 – 450 bar – 60 Hz | ||||||||||

| I 22.2-22 | 870 | 52.5 | 30.7 | 450 | 6525 | 4 | 1180 | 22 | 710 | 1565 |

| I 22.2-37 | 1300 | 76.8 | 45.2 | 450 | 6525 | 4 | 1770 | 37 | 830 | 1830 |

High-pressure compressor K 22 – K 28, 980 l/min, 420 – 525 bar – 60 Hz | ||||||||||

| I 22.5-30 | 980 | 58.8 | 34.6 | 525 | 7600 | 5 | 1170 | 30 | 780 | 1720 |

¹ Free air delivery according to ISO 1217, power consumption at maximum final pressure under certain conditions. Other ambient conditions result in different performance data.

² Max. operating pressure = max. safety valve pressure setting; reduced switch-off pressure.

Downloads for BAUER air-cooled compressors: K 22 – K 28 large-scale block

BAUER Compressors for Industry – Tailored to your requirements