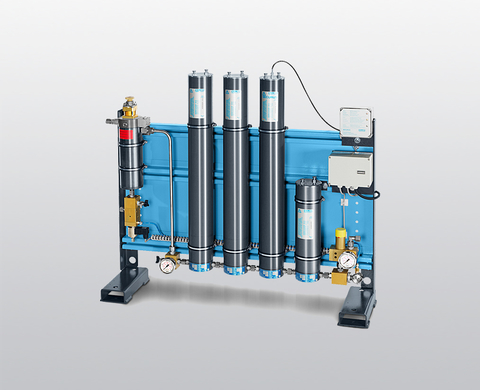

P-filter system/TRIPLEX system

BAUER P-filter systems (P stands for the German word Patrone, cartridge in English) can be relied upon to remove all hazardous substances, enabling you to breathe in clean breathing air.

Depending on the cartridge selected, BAUER P-filter systems are able to adsorb residual moisture,oil vapour, traces of hydrocarbon gases and carbon monoxide. With BAUER P-filter systems, all of the requirements of DIN EN 12021 for breathing air are not only met but even exceeded.

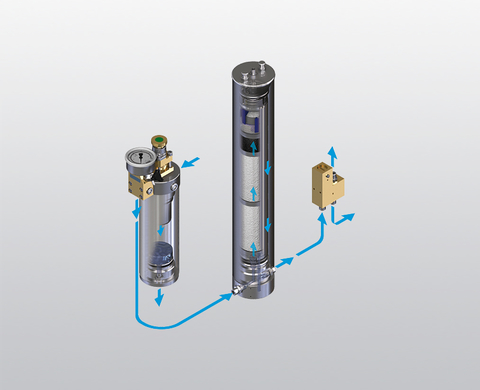

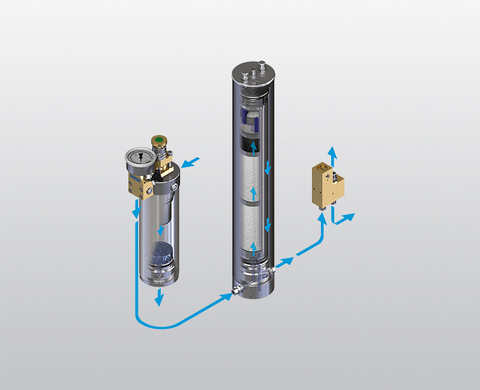

The compressed air is fed out of the compressor block and into the final separator, where the condensate (a mixture of oil and water droplets) is mechanically separated and discharged safely through the condensate drain valve.

The air cleaned upstream then flows through the P-filter system, which adsorbs the remaining water in the form of steam, removing hazardous contents from your breathing air at the same time.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

All the information you need at your fingertips!

The technology of each and every P-filter cartridge is perfectly matched to the corresponding BAUER P-filter system. Original BAUER filter cartridges with premium quality filter materials ensure that oil, moisture, oil vapour, hydrocarbon compounds, coarse impurities or minute particles are effectively removed from the compressed air.

The ideal P-filter cartridge composition for each application is formulated, optimised and reliably tested in the BAUER quality testing centre.

Original BAUER filter cartridges benefit from a perfectly harmonised ratio of activated carbon to molecular sieve. Compliance with the strict limit values specified in the applicable standards for breathing air and air used in medical applications (e.g. according to DIN EN 12021 and the European Pharmacopoeia) is thereby assured. In many cases, using a BAUER P-filter system will even lead to the requirements of the corresponding standards being exceeded¹.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

The filter housings are subject to seamless checks and documentation. BAUER KOMPRESSOREN is a certified manufacturer in accordance with the EU Pressure Equipment Directive.

The housings of the BAUER KOMPRESSOREN P-filter system (filter housings) are made exclusively from special aluminium alloys or chemically nickel-plated high-strength steel. This is the reason why BAUER filter housings can be relied upon to withstand ultra-high pressures of up to 500 bar and thousands of load cycles.

Filter cartridges filled by customers or cartridges from third-party manufacturers are hazardous to health due to their poor filter performance: downstream systems can suffer corrosion, ice up and become contaminated.

B-TIMER filter monitoring unit

The B-TIMER, which has been developed for BAUER high-pressure compressors, not only displays the operating hours but also the current level of cartridge saturation. The B-TIMER flashes when a cartridge change is due. At the same time, the purchase order of the filter cartridge required is shown on the display. This ensures that the very best use is made of the filter's capacity. In order to benefit from these functions, you must use an original BAUER filter system. Read more

B-SECURUS filter monitoring unit

The B-SECURUS system monitors the saturation of the filter cartridge(s) by measuring the moisture in the molecular sieve and outputs a warning on the display or the compressor control in advance of when the filter cartridge should be changed. B-SECURUS automatically switches the compressor unit off if the cartridge is saturated and has not been changed. The B-SECURUS filter monitoring unit can only be used in conjunction with P 41/P 42/P 61/P 81 filter systems and external BAUER filter systems. Read more

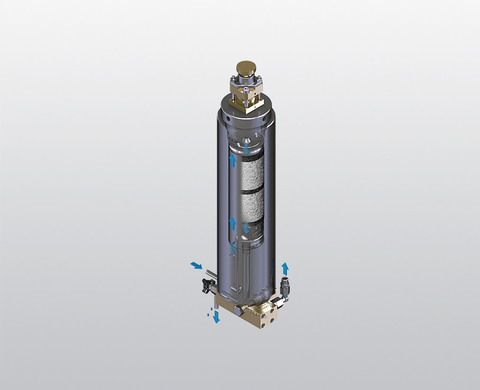

Scope of delivery, P 21

- Filter housing with integrated oil and water separator

- Filter cartridge appropriate for intended use

- Pressure retention valve

- Condensate drain valve

- Final pressure safety valve 059410

Scope of delivery, P 31

- Filter housing with integrated oil and water separator

- Filter cartridge appropriate for intended use

- Pressure retention valve, integrated in base of housing

- Check valve, flange-mounted on filter base

- Condensate drain valve

Scope of delivery, P 42

- Filter housing with integrated oil and water separator

- Filter cartridge appropriate for intended use

- Pressure retention valve

- Bleed valve

Scope of delivery, P 41 to P 81

- Filter housing including 1 set of filter cartridges

- Check valve with pressure gauge and bleed

- Pressure retention check valve

- Screw fittings and 0.5 m piping to connect the components

- Key for filter housing to change the filter cartridges

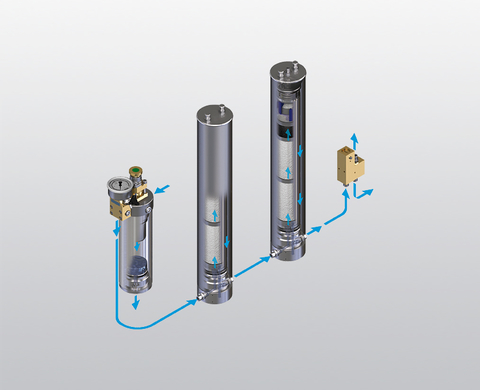

Scope of delivery, P 80 to P 140

1 filter console, to which the following are attached and connected via piping:

- Oil and water separator with micro-filter cartridge

- Condensate drain valve, manual (autom. condensate drain available at additional cost)

- Filter housing with 1 set of filter cartridges

- Combined pressure retention and check valve

- Bleed valve

- Pressure gauge

- Key for filter housing to change the filter cartridges

Downloads for the P-filter system

BAUER Accessory Systems – The ideal enhancement to your compressor